Additive Manufacturing (AM), commonly known as 3D printing, is transitioning from prototyping to industrial-scale production. As process complexity grows, manufacturers are facing tighter quality, traceability, and certification requirements. IP cameras, originally designed for surveillance, are increasingly becoming a practical tool for real-time process visualization in AM environments due to their flexibility, scalability, and network connectivity.

Why Process Visualization Matters in Additive Manufacturing

Unlike traditional manufacturing, AM builds parts layer-by-layer, where defects can form and propagate internally without being visible in the final product. Effective process visualization enables:

- In-situ defect detection (e.g., spatter, warping, layer delamination)

- Thermal and melt-pool behavior monitoring

- Build-chamber event traceability

- Remote expert supervision

- AI-based closed-loop process control integration

Visualization is not only about observation—it is the foundation for actionable quality intelligence.

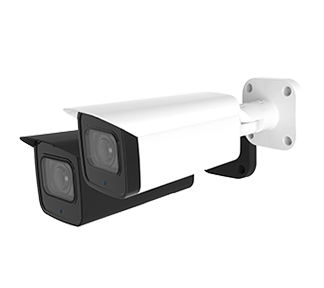

Typical IP Camera Deployment in AM Systems

1 External Monitoring

- Installed outside the chamber viewport

- Used for build progression recording, operator behavior, and certification evidence

2 Internal Chamber Visualization

- Protected with thermal shielding, air-knife purge, or isolated optical windows (glass bubble composite windows could be relevant for EMI/thermal-safe enclosures)

- Monitors powder recoating, laser path sparks, and deposition behavior

3 Multi-Camera 3D Observation

- 2 to 4 cameras mounted at different angles

- Enables spatial reconstruction or digital twin visualization of the print process

Integration with AI and AM Quality Management

IP camera streams can be fed into machine-vision or AI models to detect anomalies such as:

- Excessive spatter bursts

- Powder bed irregularities

- Surface deformation trends

- Unexpected chamber events

This supports data-driven process certification, similar to machine-vision systems used in medical injection molding—another domain you’ve explored.

Real-World Applications

IP cameras are already used in:

- LPBF metal printing build-chamber observation

- WAAM robotic welding deposition recording

- Binder-jet recoating process tracking

- Factory-wide remote supervision dashboards

- Marketing demo visualization on mobile LED trucks during AM exhibitions (fits your OOH activation interest)

IP cameras are not a replacement for scientific high-speed vision or thermal sensors, but they provide an accessible, scalable, and integrable visualization layer for additive manufacturing environments. When engineered with proper chamber protection and AI integration, they evolve from simple video feeds into a strategic quality management asset.