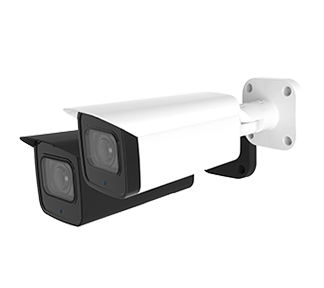

In hazardous industrial environments, surveillance equipment must go beyond image quality and motion control—it must be engineered to prevent ignition risks, withstand extreme conditions, and comply with strict safety certifications. Explosion-safe PTZ (Pan-Tilt-Zoom) cameras provide 360° coverage, remote-controlled patrol, and auto-tracking while operating safely in locations containing flammable gases, vapors, or dust.

These systems are widely used in oil & gas facilities, chemical plants, grain processing sites, mining zones, fuel depots, and LNG storage terminals—areas where a single spark can have catastrophic consequences.

What Makes a PTZ Camera “Explosion-Safe”?

An explosion-safe PTZ camera incorporates multiple safety layers:

- Non-sparking enclosure materials (typically 316L stainless steel or corrosion-resistant aluminum alloys)

- Pressure-tight or flameproof housings that contain internal electrical faults

- Sealed cable glands and connectors to eliminate gas or dust ingress

- Low-temperature surface operation to avoid exceeding ignition temperature limits

- Protected pan-tilt motors to prevent friction-generated sparks

- Intrinsic safety barriers for control and communication lines when required

Hazardous Location Classification & PTZ Selection

Explosion-safe PTZ cameras are commonly installed in:

- Zone 1 / Class I, Div 1 → explosive atmosphere likely during normal operation

- Zone 2 / Class I, Div 2 → explosive atmosphere possible but not frequent

- Zone 21 / 22 or Class II → combustible dust environments

- T-Class (T1–T6) areas → defines maximum surface temperature of the device

PTZ camera hardware must be matched precisely to the hazard profile, especially gas group (e.g., IIA, IIB, IIC) and temperature class.

Design Features That Improve Safety + Performance

1. 316L Stainless Steel Housings

- Best for corrosive, coastal, or chemical exposure

- Non-sparking, high durability, ideal for harsh plants (aligns with your interest in stainless steel security doors and industrial hardware reliability)

2. Low-SWaP Thermal Management

- Efficient heat dissipation prevents enclosure hot-spots

- Enables safe operation in high-duty patrol or continuous motion

3. Anti-Vibration Mounting

- Prevents blurry footage and motor wear in industrial plants or mobile platforms (you already have interest in vibration-resistant mounting systems for LED trucks and PTZ units)

4. High-Torque Protected Motors

- Smooth pan-tilt movement without friction ignition risk

- Long-life design for 24/7 rotation cycles

5. Sealed Explosion-Proof Cable Glands

- Prevent gas ingress

- Maintain flameproof integrity of the housing

Deployment Best Practices

- Mount at high points to maximize coverage and reduce blind zones

- Use certified Ex-rated power supplies or isolators

- Keep communication lines protected using safety barriers when needed

- Enable PTZ patrol presets to reduce manual control workload

- Use fiber or shielded cables for long runs in noisy industrial zones

- Avoid direct mounting on vibrating machinery—use shock-absorbing brackets instead

Integration with Modern Monitoring Systems

Explosion-safe PTZ cameras are typically integrated into:

- Hybrid NVR or VMS platforms

- Remote control via ONVIF, RTSP, or secure API

- Incident analytics using edge-AI telemetry

- Multi-site monitoring dashboards

Explosion-safe PTZ cameras are essential for surveillance in hazardous locations where safety is non-negotiable. By combining flameproof housings, non-sparking materials, low-temperature operation, vibration-resistant mounts, and certified cable systems, these cameras provide full situational awareness while eliminating ignition risks.